IFS Applications Integration with Field Service Management Tools: A Competitive Outlook

Table of Contents

ToggleIFS Applications integration with field service management software is transforming how service-driven businesses operate — from real-time visibility and predictive maintenance to automation and mobile-first execution.

This blog explores how IFS Applications modules like ERP, EAM, and FSM work together to streamline field operations, reduce inefficiencies, and enhance customer satisfaction. From consulting to customization, it highlights the competitive advantages and technical capabilities that make IFS Applications software a game-changer.

Whether you’re modernizing manufacturing or scaling service operations, IFS Applications integration services from Tntra deliver the tools to lead in the Industry 4.0 era.

Why IFS Applications Integration Matters

Field service management was once a linear, schedule-and-dispatch model. Today, it’s dynamic, data-driven, and connected — powered by intelligence, automation, and cloud integration.

What integration solves

At the core of this transformation lies IFS Applications integration. Whether you manage thousands of technicians across regions or are just starting to digitize, integrating IFS Applications with your field service management software gives you the competitive edge to run smarter operations.

Beyond the Basics: How IFS Integration Adds Value

Many businesses already have ERP or CRM systems in place alongside standalone field service management tools. However, disconnected systems lead to data silos, delays, and inefficiencies.

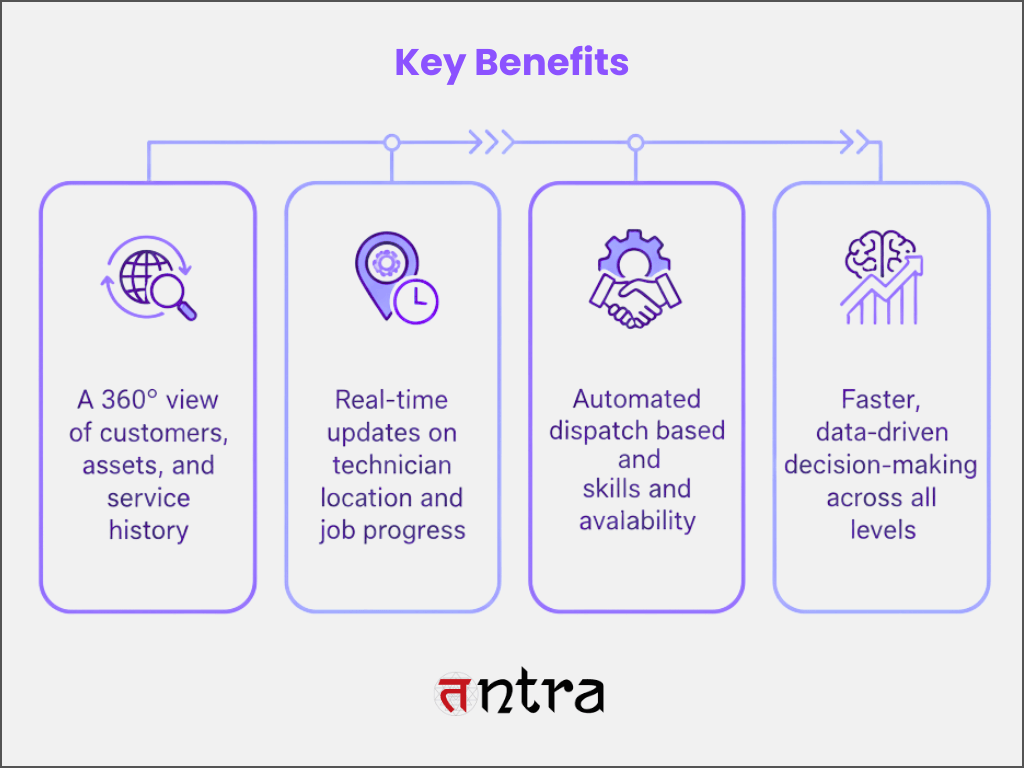

That’s where IFS Applications integration with field service management software becomes crucial. By connecting finance, inventory, HR, and asset management with real-time field operations, organizations unlock.

What are IFS Applications?

Let’s break it down simply.

IFS Applications is a powerful enterprise suite designed for industries that rely heavily on assets, projects, and field services. These include manufacturing, energy, utilities, telecommunications, aerospace, construction, and more.

The suite consists of various modules that can be deployed together or selectively, including:

Key IFS Applications Modules

- IFS Field Service Management (FSM) – for scheduling, dispatching, and customer engagement.

- IFS ERP Module – manages finance, HR, and supply chain operations.

- IFS Enterprise Asset Management (EAM) – supports maintenance and asset lifecycle tracking.

- IFS Project and Work Order Management – links project tracking, budgets, and execution.

- IFS Supply Chain and Procurement – ensures smooth flow of parts and inventory.

The strength of IFS Applications software lies in how seamlessly these modules integrate — especially when connected with the best field service management software solutions.

IFS Applications Integration: The Core of Service Efficiency

Integration isn’t just about connecting data — it’s about intelligent communication between systems. With IFS Applications integration, your back office, technicians, and customers work as one ecosystem.

1. Unified Data for Smarter Operations

Technicians gain real-time access to:

- Customer details and service history

- Equipment data and warranties

- Parts availability and invoices

No more switching tools or calling dispatch — everything is available through IFS Applications.

2. End-to-End Automation

From service request to invoicing, IFS Applications customization and deployment can automate every step — reducing manual intervention and improving turnaround times.

For insights on modern automation in service delivery, explore 5 Warning Signs It’s Time to Upgrade to IFS Service Management.

3. Proactive Maintenance with IoT Integration

With IoT integration and predictive maintenance, IFS enables organizations to detect issues before failures occur. Technicians are automatically alerted, spare parts are pre-dispatched, and downtime is minimized.

Learn how IFS FSM Software Automates Field Service and Reduces Downtime.

IFS Applications Modules that Power Field Service

- IFS Field Service Management Module: This is the heart of your field operations. It handles dispatching, scheduling, technician tracking, mobile access, and customer interactions.

- IFS ERP Module: Handles finance, supply chain, procurement, and HR, ensuring field teams have the support they need, from salaries to spare parts.

- IFS Enterprise Asset Management (EAM): Perfect for asset-heavy industries. Helps track asset lifecycle, schedule maintenance, and plan capital expenditures efficiently.

- IFS Project and Work Order Management: Allows you to track long-term projects and job-specific activities in the same interface, linking budgets, teams, and timelines with real-time updates.

When these IFS Applications modules are connected with your field service management software, they become far more powerful than when used alone.

Implementation, Customization, and Support: The Human Side of IFS

A successful IFS Applications implementation depends on three things:

1. Strategic Consulting

Expert IFS Applications consulting helps you map your business processes, identify integration opportunities, and avoid pitfalls. Consultants also guide you through compliance, change management, and performance measurement.

2. Customization for Your Needs

Not every business fits into a template. Whether it’s automating specific service workflows, creating custom dashboards, or modifying user roles, IFS Applications customization ensures the platform works for you, not the other way around.

3. Ongoing Support and Upgrades

A well-executed IFS Applications upgrade ensures you benefit from the latest features without disrupting operations. With proactive IFS Applications support, bugs are resolved quickly, user adoption remains high, and system performance is optimized consistently.

To understand how enterprises maximize ROI through seamless integration, explore IFS Success Strategy: Support Innovation and Maximize ROI.

ERP and Field Service Management Integration: A Must-Have Strategy

Integrating ERP and field service management systems eliminates silos and drives efficiency by enabling:

Integration outcomes

- Real-time inventory visibility

- Mobile-first field operations

- Regulatory compliance

- First-time fix improvement

- Scalable operations with reduced costs

With IFS Applications integration services, you’re not patching systems — you’re designing an intelligent, connected enterprise. For a detailed view, see Why IFS ERP Cloud Matters for Modern Enterprises.

IFS Applications for Manufacturing and Asset-Intensive Industries

For manufacturers, IFS Applications for manufacturing bridges ERP and field service operations.

Manufacturing-specific benefits

- Full product traceability and recall readiness

- Predictive maintenance via IoT data

- Enhanced after-sales service visibility

From the shop floor to the customer site, IFS Applications integration ensures end-to-end control and efficiency.

Learn how Industrial AI and IFS Cloud Drive Smart Manufacturing to achieve better outcomes.

Field Service Management Software Comparison: IFS vs Competitors

| Feature | IFS FSM + IFS ERP | SAP FSM | Oracle FSM |

| Industry Focus | Manufacturing, Telecom, Energy | Manufacturing, Utilities | Telco, Construction |

| Modular Flexibility | Highly modular | Requires tight SAP stack | Tightly coupled |

| Cloud Options | Cloud-native | On-prem & cloud | Cloud-first |

| Integration Simplicity | Built-in APIs, Fast IFS API integration | Complex | Moderate |

| Customization | High | Moderate | Limited |

| Field Mobility | Best-in-class mobile tools | Good | Good |

IFS Applications integration clearly leads in modularity, customization, and deployment speed.

IFS API Integration: The Technical Advantage

Integration targets

IFS API integration bridges systems seamlessly with:

- Salesforce Field Service IFS integration

- IoT platforms for predictive maintenance

- Mobile workforce integration IFS

- AI/ML engines for intelligent automation

This flexibility supports both legacy modernization and greenfield digital transformation. For a deeper comparison, check IFS ERP vs SAP: Complete Manufacturing ERP Comparison.

A Day in the Life with IFS Field Service Integration

Sample technician workflow

- 8:00 AM – Technician receives optimized route jobs.

- 9:00 AM – Reviews service history via IFS app.

- 10:30 AM – Logs maintenance data; IoT triggers next action.

- 11:00 AM – IFS auto-orders parts, schedules follow-up.

- 12:00 PM – Customer receives status and feedback form.

That’s IFS Applications integration in real-world action.

Conclusion: Building the Connected Service Enterprise

Strategic value

IFS Applications integration is more than operational alignment — it’s strategic transformation.

From IFS Applications consulting and implementation to customization, deployment, and support, Tntra helps organizations unlock agility, scalability, and intelligence in every operation.

When you connect IFS Applications software with the best field service management software, you don’t just optimize workflows — you redefine service excellence.

Quick Recap for Decision-Makers

Key takeaways

- IFS Applications modules empower manufacturing, utilities, and telecom sectors.

- ERP and field service management integration drives efficiency.

- Real-time data enhances productivity and decision-making.

- IFS customization and consulting ensure seamless rollout.

Ready to scale smarter?

Talk to Tntra’s IFS experts today to explore IFS Applications integration services for your business.

FAQs

1. What is IFS Applications integration and why is it important for field service management?

IFS Applications integration connects ERP, EAM, and FSM modules for real-time synchronization, improving technician productivity, asset tracking, and customer experience.

2. How does IFS API integration improve operational efficiency?

IFS API integration bridges systems like CRM, IoT, and mobile tools, automating workflows and enabling seamless data exchange across departments.

3. What are the benefits of ERP and field service management integration?

It eliminates data silos, reduces manual errors, enhances decision-making, and ensures real-time operational visibility across service and back-office functions.

4. Which industries benefit most from IFS Applications for service management?

Manufacturing, utilities, energy, telecom, and aerospace industries benefit the most due to asset intensity and the need for integrated maintenance and service operations.

5. How can Tntra help with IFS Applications implementation and support?

Tntra provides end-to-end IFS consulting, implementation, customization, and support to ensure successful integration and continuous optimization.

Download IFS Guide

Download IFS Guide