The Rise of IoT in Japanese Supply Chain Management

Table of Contents

ToggleSummary

The Japanese supply chain market is witnessing a massive transformation. Technology is taking over, and IoT has become a driving force in optimizing logistics operations. GPS tracking devices, sensors, and predictive maintenance systems have changed how the manufacturing industries used to work. The impact of IoT in the Japanese supply chain management industry is massive. Key IoT technologies are playing a critical role in improving supply chains across the nation.

NTT and Nippon Express: Transforming Supply Chain with Blockchain and IoT Innovation

Nippon Telegraph and Telephone (NTT), a leading Japanese telecommunications company, built a platform that combines Blockchain and supply chain Innovation with IoT. By using RFID and Blockchain, NTT was able to better its logistics and supply chain operations.

The technology enabled the company to improve the efficiency of inventory financing based on Blockchain and IoT-enabled track and trace technology. It helps them trace products at every stage of the manufacturing process. Similar offerings are available at almost every Japan Software Development company these days.

Another example comes from Nippon Express, the Japanese pharmaceutical company. The company transformed its methods of supply chain management (SCM). It partnered with Accenture to develop a cloud-based tracking system. Using IoT, they put Intel’s electronic tags on each pharmaceutical shipment.

The information is uploaded to the cloud when the shipments pass through warehouses or such. It empowers Nippon Express to track their shipments in real-time and tackles any challenges that may arise.

Source: Accenture, Orange Business

IoT Impacts The Japanese Supply Chain Market at Light Speed

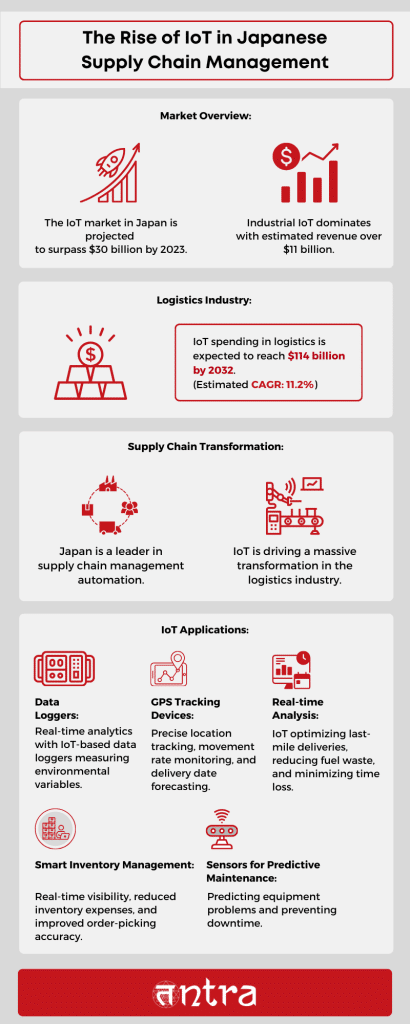

The Internet of Things (IoT) market in Japan is expected to reach over $30 billion by the end of 2023. Industrial IoT dominates the market with an estimated revenue of over $11 billion. The supply chain segment is one of the most critical parts of industrial IoT in nearly every industry.

The IoT spending in the Logistics industry is expected to reach $114 billion by 2032. The estimated CAGR is 11.2%. IoT is one of the most used technologies in the supply chain management segment.

IoT in Logistics: Changing The Way Supply Chains Work

Japan is one of the leaders in supply chain management. The logistics industry is witnessing a massive transformation – all thanks to the interesting technology that brings ideas to life.

The Internet of Things in supply chain management has emerged as a key player in optimizing logistics processes in Japan. RFID tags, sensors, and more are simplifying the whole supply chain.

Let’s look at the impact of IoT on supply chain management and how it enables supply chain systems, with the integration of cutting-edge supply chain management software solutions, to achieve efficiency and operate at their fullest.

- IoT-based Data Loggers

- Real-time analytics can be performed on shipments using IoT-based data loggers. To ensure the proper condition of the transported items, these tools measure many environmental variables, including temperature, tilt angle, shock, humidity, and more. Data loggers transmit their measurements to centralized data management systems, facilitating effective data recording, analysis, and decision-making.

- For example, the data logging business has developed data logging tools with QR tags fastened to the sensors. By scanning a QR code with your smartphone, you can easily submit updated condition data from any point along the supply chain to a cloud-based server or database.

- GPS Tracking Devices

- A company may precisely track the location of items by integrating IoT solutions with the full supply chain’s path. Additionally, you may monitor the movement rate and forecast the products’ arrival date. Thanks to GPS-equipped IoT devices, businesses always know where their products are in real time. The sensors and associated gadgets can be fastened to the products or storage containers.

- Delivery hiccups can cost businesses a lot of money. Unexpected setbacks may result from pandemic-related interruptions or geopolitical conflicts, to name a few. Businesses can save a lot of time and money by knowing a product’s precise location and anticipated delivery date. Managing the manufacturing pipeline is made easier by tracking the movement of commodities.

- Sensors for Predictive Maintenance

- Utilizing data and analytics to predict and stop equipment problems and downtime is known as predictive maintenance. By gathering and delivering real-time data from sensors attached to equipment, cars, and other assets, IoT in supply chain management solutions can enable predictive maintenance.

- Artificial intelligence or cloud-based software can analyze this data to look for patterns, spot anomalies, and predict errors. By doing this, you may plan maintenance tasks for when issues first arise, lower repair expenses, increase the lifespan of your equipment, and prevent disruptions.

- Smart Inventory Management Systems

- Real-time visibility across warehouses, production facilities, and distribution centers is made possible by smart inventory management using IoT-based supply chain systems. For instance, sensors placed on shelves send its management system real-time inventory data.

- Because there is less physical labor, inventory expenses are decreased. Many times, electronic parts are offered in kits that may contain hundreds of SKUs. With IoT data, order-picking accuracy increases considerably.

- IoT devices can also notify warehouse operations when a certain stock is running low on supply so that it can be ordered ahead of time. This strategy helps to avoid supply chain problems and late deliveries.

- Real-time Analysis

- The last mile—the distance from the local distribution center to the final destination—is typically the most expensive and wasteful portion of the distribution process, even though the items travel thousands of miles across the globe to reach the client. According to a 2019 Capgemini analysis, last miles account for 41% of supply chain expenses.

- IoT is the ideal answer for businesses trying to improve because last-mile deliveries require time. GPS and IoT can find the best routes to reduce fuel waste and time loss due to traffic. All of this is made feasible by the Internet of Things’ real-time traffic analytics and trouble notification capabilities.

Unlock efficiency, streamline processes, and drive success with Tntra’s Workflow Management Solution. Read the case study now!

IoT makes the Supply Chain Stronger, Faster, and Better

Japan is the hub of manufacturing companies, and supply chain management plays a crucial role in determining the success of these manufacturers. As IoT technology multiplies by leaps and bounds, Japanese companies look for innovative ways to optimize and improve their supply chain. In this landscape, partnering with advanced supply chain solutions companies becomes essential. These companies leverage IoT technology to provide innovative solutions for efficient and streamlined supply chain management, addressing Japanese manufacturers’ unique challenges.

IoT brings new opportunities for supply chain management that weren’t possible earlier. It provides efficiency, sustainability, and, most importantly – higher visibility of what’s going on during each phase of the process.

By leveraging IoT for the supply chain solutions, companies can optimize their supply chain and unlock new possibilities for growth.

Are you looking for a IP-led software product engineering company that can help optimize your supply chain operations in Japan? Tntra is a trusted custom supply chain software development company for businesses that must integrate IoT and future-proof their supply chain operations.

Get a FREE CONSULTATION today. Contact us now!