How to Overcome the Global Supply Chain Challenges with Software Development Technology?

Supply chain management software solutions are helping to solve supply chain problems efficiently. These technologies’ automation, real-time visibility, and predictive analytics allow firms to streamline processes, improve transparency, and spur expansion. By utilizing software technology, organizations can address challenges, including intricate logistics, rising customer expectations, and globalization. By streamlining procedures, reducing human error, and enabling businesses to make informed decisions, integrating these technologies improves supply chain efficiency and profitability.

An international energy business, Shell operates in the oil, gas, and renewable energy sectors. It has a lengthy history dating back over a century and is renowned for its ingenuity, dedication to sustainability, and wide range of business endeavors. The company has been essential in supplying the globe with energy.

To manage and reduce risk concerns in its worldwide supply chain, Shell collaborated with Accenture and UK-based data intelligence business Ripjar. The partnership intended to strengthen Shell’s operations’ risk screening skills and risk management procedures.

Shell aimed to create a robust supply chain management process to safeguard its supply chain from illegal activity by utilizing AI and automation technology from Ripjar. This strategic endeavor demonstrates Shell’s dedication to implementing cutting-edge solutions and safeguarding its supply chain operations’ security and integrity.

In the current global commercial environment, Shell has proactively addressed the growing difficulties connected to fraud, security, and criminal behavior. Shell upgraded data insights for enhanced accuracy and thorough audit capabilities, replacing time-consuming manual processes with cutting-edge automation to strengthen risk management throughout its supply chain.

By putting this solution on Microsoft Azure, Shell guaranteed scalability and cost-effectiveness while enhancing accessibility for employees worldwide with self-service capabilities. Using AI-enhanced technology from Ripjar, the supply chain can be continuously monitored in real-time to identify hazards and enable quick response and mitigation.

Source: Accenture

Challenges in Supply Chain Management and Software Solutions

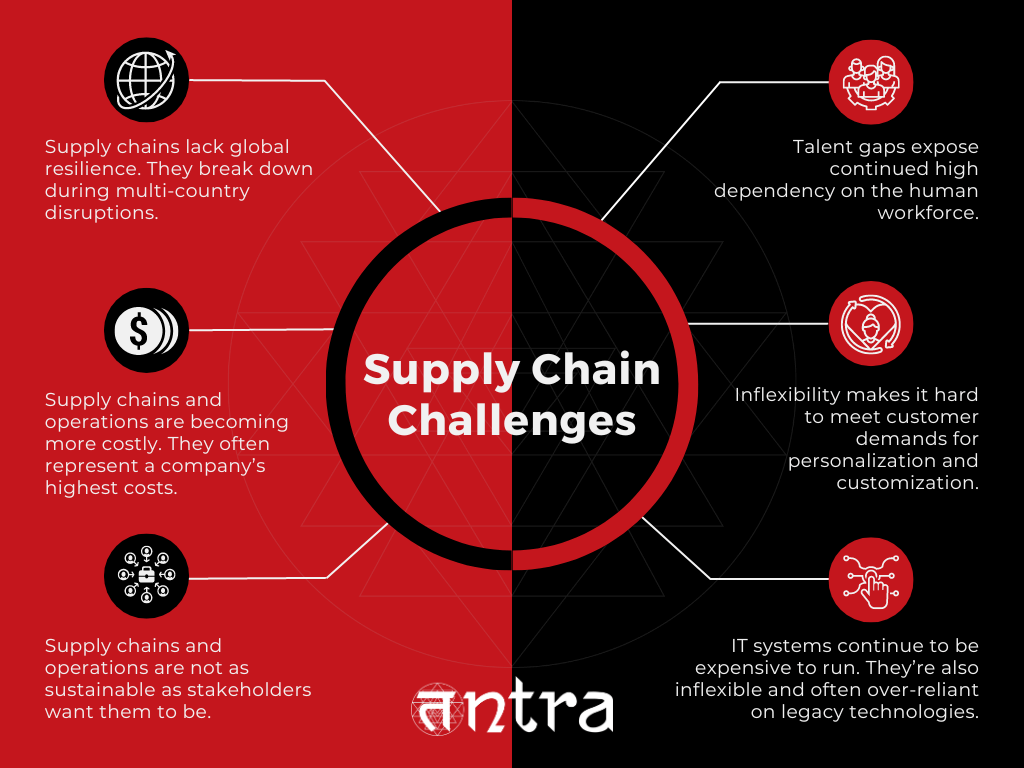

About 60% of consumers, or a sizable fraction, experienced disappointment in 2022 when they couldn’t get the things they wanted because of supply chain limitations. Customers’ negative emotional responses to this scarcity included 61% feeling frustrated, 46% being impatient, 45% feeling anxious, and 34% feeling angry. These findings show how seriously supply chain disruptions affect consumer sentiment, highlighting how urgent it is for companies to handle and reduce shortages to increase customer happiness and preserve brand loyalty.

Disruptions in the supply chain have a wide-ranging effect, hurting customers and enterprises. These disruptions had unfavorable effects on about 75% of businesses. Inventory shortages and disruptions can affect up to 4% of inventory for major businesses but up to 40% of inventory for smaller businesses.

In 2023, though the supply chain challenges have reduced, businesses are playing with caution and adopting various supply chain software solutions as a proactive approach. The value of the Global Supply Chain Management Software market is worth $18 billion and is expected to rise at a CAGR of 12.25% over the next five years. By 2028, it’s anticipated to reach $36 billion.

The AI/ML, automated supply chain management solutions, have significantly contributed to supply chain challenges, as exemplified by Amazon’s utilization of machine learning algorithms to optimize warehouse operations, resulting in a 50% reduction in operating costs and a 60% increase in warehouse capacity.

Similar to the previous example, IoT-based software solutions have accelerated growth in the supply chain industry, with the top use cases being asset tracking, predictive maintenance, condition monitoring, quality control, and supply chain management.

How to Overcome the Supply Chain Challenges with Software Technology?

Digitalization significantly transforms the supply chain industry. Companies are implementing cutting-edge technologies in their supply chain operations to spur corporate innovation and growth in response to the challenges posed by escalating globalization, complex products, and changing client needs. Thanks to digital transformation, organizations are better equipped to negotiate these shifting environments and maintain an advantage in the cutthroat market.

Here are some top recommendations for using software-based supply chain solutions to achieve efficiency in industrial operations and manage challenges in the global SCM –

- Use of Blockchain

- Blockchain technology in the supply chain can significantly reduce challenges in the global supply chain. Its immutability makes it possible to accurately monitor the origin of items and builds trust in supplier information and supply chain processes.

- In contrast to conventional techniques like email or bookkeeping, Blockchain efficiently produces an audit trail. Blockchain-powered track-and-trace use cases assist in identifying fake goods, detecting fraud, identifying at-risk suppliers, ensuring regulatory compliance, and improving product movement transparency.

- Enhanced traceability and transparency in supply chain processes.

- Supply chain technology improves efficiency and accuracy in tracking goods’ origin and custody.

- Increased trust in supplier information and data integrity.

- Effective detection and prevention of counterfeit items and fraud instances.

- Use of AI/ML Based Supply Chain Management Software Solutions

- AI/ML-based tech-led supply chain management solutions bring multiple advantages. Processes in the supply chain can be digitized and automated to eliminate human error and enhance customer satisfaction.

- Strategic decision-making is enabled by real-time visibility and predictive analytics, which take advantage of big data insights. AI and ML optimize supply chain operations by improving forecasting, planning, and automation, reducing risks and increasing efficiency.

- Blockchain and AI, logistics management solutions improve the connection of the supply chain by enabling end-to-end integration between suppliers, clients, and partners. ML and data analytics to improve routes and decrease waste are all ways sustainability is promoted.

- AI and ML-based automated supply chain technology also address last-mile logistics issues, which optimizes cost, service, and asset utilization. These innovations transform supply chain management, boosting productivity, client happiness, and company expansion.

- Automation and digitization of supply chain processes, reducing human error and enhancing customer experience.

- Real-time visibility and predictive analytics for informed decision-making and optimization.

- Improved supply chain connectivity through AI and blockchain technology.

- Sustainable practices through ML and data analytics, optimizing routes, and reducing waste.

- Use of IoT Solutions for Seemless Supply Chain Processes

- A supply chain software development company like Tntra is crucial in providing an IoT-based SCM solution. With the booming global IoT spending, Tntra helps supply chain industry players capitalize on the potential of connected devices for enhanced operations.

- Manufacturers and transportation businesses can use software product engineering services to develop IoT solutions that support manufacturing processes, monitor production assets, and manage freight fleets. An SCM system can help firms track locations, monitor weather conditions, examine traffic patterns, and make informed decisions using IoT and Artificial Intelligence.

- This enables suppliers to enhance the efficiency of the supply chain by optimizing delivery routes and resolving difficulties, thus dealing with SCM challenges as they arise.

- Increased supply chain transparency and efficiency through improved visibility and real-time tracking of the goods.

- Improved asset management, which optimizes utilization and reduces downtime.

- Predictive analytics and proactive maintenance for smoother operations and fewer interruptions.

- Dynamic rerouting, which adapts quickly to changing circumstances, increases delivery accuracy and customer happiness.

Unlock the Secrets to Streamlined Freight Forwarding! Discover Tntra’s Freight Forwarding Case Studies Today.

Conclusion

The adoption of software technology in logistics and supply chain management has become crucial for overcoming the challenges faced in today’s complex business environment. By harnessing the power of Blockchain, companies can enhance traceability, transparency, and trust in their supply chain processes. AI/ML-based solutions enable automation, real-time visibility, and predictive analytics, driving efficiency and informed decision-making. Additionally, IoT solutions offer seamless integration and optimization of supply chain processes, improving transparency and responsiveness.

Embracing these technologies empowers organizations to navigate supply chain challenges with agility, ensuring enhanced productivity, customer satisfaction, and overall business success in the ever-evolving landscape of logistics and supply chain technology.

Get expert guidance in implementing the ideal software technology for your unique supply chain requirements.

Contact Tntra to discuss your challenges and goals and find a tailored solution for your organization.